Member Profile

An American multinational medical devices and healthcare company with over $30B in revenue. With operations in 160 countries, the company manufactures products for glucose monitoring, adult and pediatric nutrition, heart pumps, and other vital healthcare solutions.

The Challenge

As part of its ongoing focus on cost reduction and process improvement, the company sought to refine its MRO purchasing strategy across seven U.S. manufacturing sites. The goal was to optimize the fragmented procurement process, which involved a mix of systems including SAP ERP and Maximo inventory management, leading to inefficiencies.

The challenges included:

- Supply base fragmentation

- Non-standard item nomenclature

- Poor data hygiene

- Misaligned sourcing strategies

- Lack of cross-site collaboration

The company recognized that these inefficiencies were impacting their bottom line and required a solution that would drive both cost savings and operational improvements.

How Amicus Helped

Amicus worked with the client to leverage our Epic Pro® platform in a two-phase approach to drive cost savings and process optimization.

Phase 1: Item Identification, Cleansing, and Sourcing

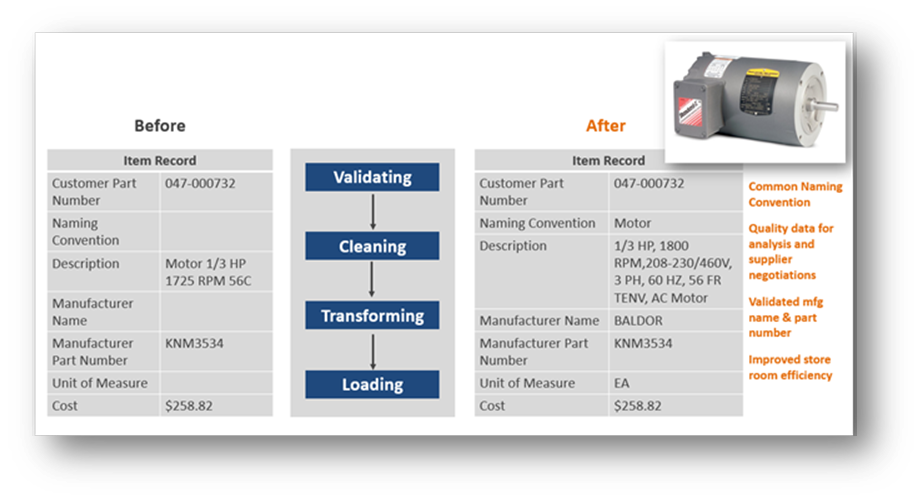

We began by initiating a customer-funded data collection and cleansing project to focus on frequently purchased items from the storeroom. Our team visited each site, armed with the client’s most recent inventory records, and over 120 days, we identified and cleaned up 16,000 items purchased over the last two years. The process involved:

- Imaging and validating items against the true manufacturer name and part number

- Cross-referencing existing items with our preferred suppliers to recommend cost-effective alternatives

- Cleaned data was integrated into the client’s inventory management systems, ensuring uniformity across all sites

By the end of Phase 1, we had standardized the item-master for the 16,000 in-scope items, making them easier to source and manage across all sites.

Phase 2: Source-to-Pay Launch

Phase 2 involved the progressive launch of Amicus’ full source-to-pay services, starting with sourcing the cleansed inventory items. As part of this phase, we:

- Conducted site visits to understand local service requirements (vending, VMI, consignment stock)

- Negotiated with suppliers to ensure the best pricing and service levels

- Implemented dedicated buyers to support daily transactional needs like spot buys and order fulfillment

Additionally, we worked with the client’s EHS team to standardize safety products, conducting site visits and sourcing solutions tailored to each location’s needs. This included developing an e-catalog for non-inventory purchases, simplifying procurement through a seamless SAP-punchout integration.

Key Implementation Elements

- Executive sponsor from the client team

- Joint workshops with subject matter experts across IT, Finance, Purchasing, and Operations

- Plant champions at each site for smoother integration

- Focus on “quick wins” by activating easily sourced items early in the process

Results

- Completed the data gathering and cleansing project for 16,000 items in just 120 days, allowing Amicus to source 7,902 unique SKUs based on manufacturer brand.

- Updated the client’s Maximo inventory master data, improving search functionality and enabling a hub-and-spoke model for inventory management.

- A comprehensive sourcing effort generated 17.3% savings, amounting to $1.72M in annual savings.

- 40% of the items were already sourced by Amicus for other clients, enabling immediate activation and savings.

- Supplier consolidation reduced the client’s vendor master list from 560 suppliers to just one, as Amicus took over order and invoice processing.

- PPE standardization savings ranged from 19% to 55% at the site level, with each site able to choose the best solution for their needs.

These efforts resulted in increased cash flow and significant ongoing savings, with additional projects in large spend categories like motors and other MRO items planned to continue the year-over-year improvement.

- CATEGORIES

- MRO