Achieving sustainability goals while reducing facility costs presents a huge challenge for all organizations. Most companies anticipate significant upfront costs to hit sustainability goals.

Still, more than 90% of CEOs state that sustainability is an important factor to their company’s health and success. Google Trends indicates that web searches related to Corporate Social Responsibility (CSR) and sustainability initiatives have risen steadily since 2007.

With sustainability on the minds of consumers and corporate executives alike, making it an organizational priority prompts the all-important question: How much will it cost? While some sustainability initiatives require significant investment and only long-term upside, here are three ways organizations can reduce operational costs and improve sustainability with minimal upfront investment.

1. Upgrade facility lighting to energy-efficient LEDs

Based on a report by the U.S. Energy Information Administration, most commercial facilities are 40+ years old. Many include older, inefficient lighting systems using fluorescent, or worse, incandescent bulbs. The average life of an incandescent bulb is 1,000 service hours and accumulates $5 a year in energy costs. The average life of an LED bulb is 25,000 service hours and costs $1 or less to power per year.

Multiplied by the number of bulbs in a single commercial facility, the energy used to power older lighting technology wastes thousands per year in utility costs.

LED lighting + lighting control systems = optimized energy sustainability

According to the Energy Information Administration, lighting accounts for 17% of electricity consumption in commercial buildings. While LED renovation in an industrial facility often saves at least 50% of lighting’s electrical consumption cost, to achieve these energy and cost savings, renovation projects often include lighting control systems.

Combined with LED lighting, the control systems allow a facility to automatically turn off lights in unused areas or during off-work periods to save energy consumption. Some lighting controls enable companies to dim lights during daylight hours, establish on/off sensors, and track real-time energy metering.

How lighting renovation pays for itself

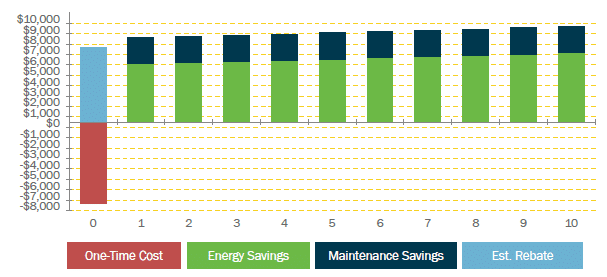

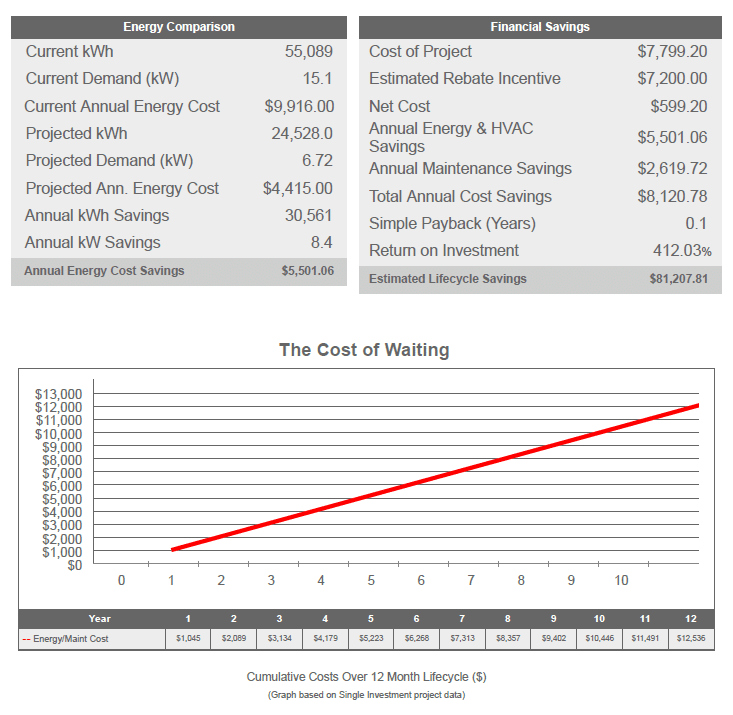

Upgrading the lighting in a facility offers tremendous value through ongoing savings. According to Graybar, most commercial lighting renovations pay back project costs in less than two years. The following financial model for one commercial facility showed the project would pay for itself within one calendar year (shown below).

While lighting renovations incur upfront costs, the combined energy and maintenance savings compound over time. As shown below, the cost of waiting to renovate increases substantially as inefficient lighting must be replaced frequently and requires more energy to sustain.

To make the case for lighting renovation more compelling, as of December 21st, 2020 Congress made permanent the Section 179D energy-efficient commercial buildings federal tax deduction. This law enables building owners to claim a $1.80 per square foot tax deduction for installing qualifying energy-efficient systems.

Tenants of commercial buildings may be eligible if they take on construction expenditures. With such a large upside to lighting renovation projects at commercial facilities, the benefit of greater sustainability is a bonus.

2. Employ vending machine solutions to reduce material waste

Commercial facilities, particularly industrial and manufacturing spaces, require maintenance, repair, and operations supplies to keep their sites running. Traditionally, sites buy MRO items such as batteries, gloves, and earplugs in bulk, then store inventory in loose bins or cabinets in the back stockroom. This often results in over-procurement of high-volume, low-dollar items, reducing traceability of employee usage and increasing general consumption.

As a result, corporate procurement teams have minimal visibility into what local sites are actively buying and using. Most companies are unaware of how much MRO costs their organization once time to procure and untracked consumption is factored in.

How Industrial Vending Machines reduce material waste

With the rise of Vendor Managed Inventory (VMI) solutions such as Industrial Vending Machines (IVM), companies can offload the tedious task of procuring operational items to trusted supplier partners. These suppliers install vending machines onsite to replace loose bin stock, coordinate with site buyers on which items and quantities to stock in the machines, track usage, and restock according to preset min/max levels.

These machines can limit how much an employee is able to withdraw and can hold them accountable for returning multi-use items. This encourages employees to track their own material usage and discourages theft. When an employee is limited in how many earplugs they can take out within a workday, they are more careful about misplacing these waste-inducing items.

While VMI vending machines reduce waste at commercial facilities, suppliers charge for their installation and restocking service. For this solution to improve sustainability and reduce costs, companies consider the total cost of ownership. VMI solutions focus on lowering the total cost of ownership in three key areas:

- Lower acquisition costs, including the cost to purchase equipment and parts

- Lower personnel costs, by reducing the human capital required for inventory management tasks, including writing POs or checking stockroom inventory

- Reduce operating costs, including unpacking, organizing, and tracking thousands of items

When companies allow suppliers to come in and restock vending machines at commercial facilities, they offload substantial administrative work and gain sustainable upside. Suppliers often restock MRO items from regional distribution centers and use returnable containers. This reduces single-use packaging and miles driven to deliver.

3. Work with suppliers to identify sustainably sourced products

Whether you are starting a lighting renovation project or selecting the items for the new industrial vending machines at your commercial facilities, you can partner with trusted suppliers to identify sustainably sourced products. Not all product details are included in the supplier catalogs and comparing the overall sustainability of Item A vs Item B can eat up valuable time.

Suppliers have a wealth of knowledge about the products in their catalog. Approaching suppliers as partners and advisors empowers you as a buyer to source more sustainable products for your sites. Pursuing a stronger relationship can pay off in more ways than greater potential sustainability.

Several organizations help pave the way toward stronger supplier partnerships. As a group purchasing organization, Procure Analytics gives you access to our existing supplier relationships. Our partners offer a wealth of supplier knowledge on procurement solutions that reduce costs and improve sustainability. If you don’t have a national account manager with your MRO supplier(s), engaging a GPO like Procure Analytics offers you national account status at no cost to you.

- CATEGORIES

- Managed Categories